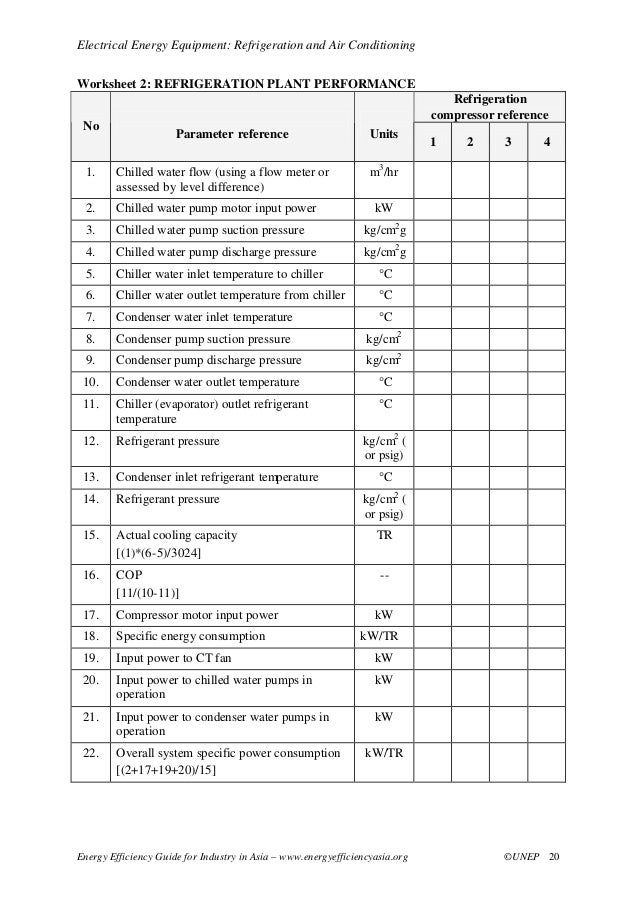

The maintenance program and plan mpp is a detailed plan customized for a cooling tower system that describes operational and administrative strategies and process control measures to be taken to prevent and control the growth of legionella.

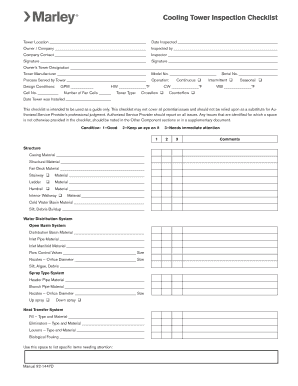

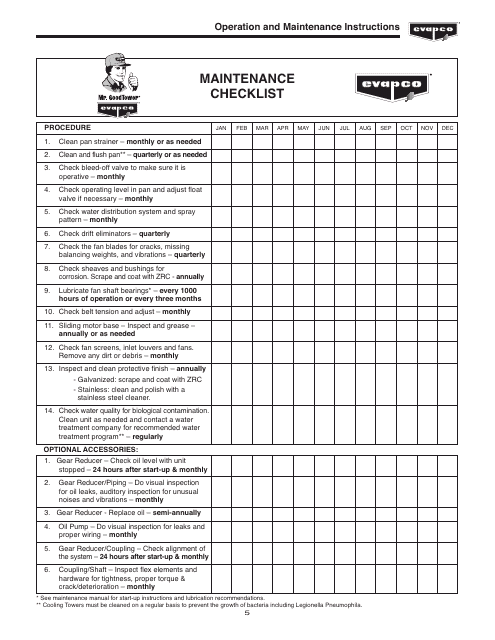

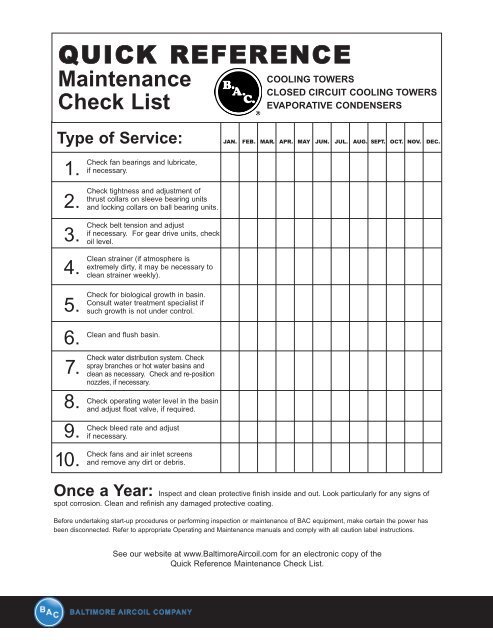

Cooling tower maintenance checklist pdf.

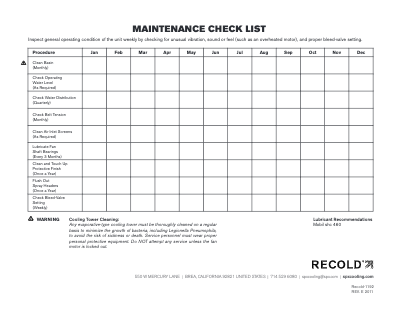

Maintenance checklist continued seasonal shut down checklist when the system is to be shut down for an extended period of time the following services should be performed.

Maintenance program and plan.

The cold water basin should be flushed and cleaned with the suction strainer screens in place.

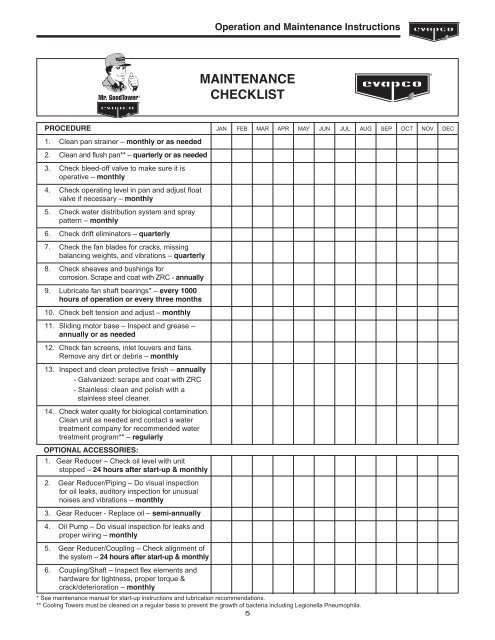

Clean and flush pan quarterly or as needed 3.

It allows you to audit the arrangements you have in place or intend to put in.

Preventive maintenance program and plan for cooling towers utica cfmu 00018 r1 printed copies are considered uncontrolled.

Keeping your cooling tower running smooth and in good shape requires more than just the annual inspection before startup.

The cooling tower casing and the water basin are made of strong corrosion proof fibreglass reinforced polyester resin.

The water basin is an integrated part of the cooling tower casing on this reason leakage is prevented for the examination of the spray nozzles and for maintenance on the adjustable float valve inspection hatches are provided.

Verify revision prior to use.

Cooling tower legionella risk assessment checklist this cooling tower risk assessment checklist takes you through the recommended measures in the health safety executives hse approved code of practice acop l8 on controlling legionella bacteria in water systems.

Clean pan strainer monthly or as needed 2.

The cost of overlooking the maintenance of a cooling tower can be heavy.

Dcn1359 page confidential 10 of 12 appendix b interpretation of legionella culture results from cooling towers interpretation of legionella culture results from cooling towers legionella test.

Check operating level in pan and adjust float valve.

The evaporative cooling unit cold water basin should be drained 2.

Keeping your cooling tower in good shape requires more than just the annual inspection before startup.

Click here for a printable pdf.

The evaporative cooling unit cold water basin should be drained.

Building an mpp team checklist pdf.

Stick to a regular maintenance schedule to reduce the risk of legionella and prevent premature failure.

Stick to a regular maintenance schedule to reduce the risk of legionella and prevent premature failure recommends dan glover technical services group manager for southland industries a national mechanical engineering construction and service firm.

Check bleed off valve to make sure it is operative monthly 4.

The cold water basin should be flushed and cleaned with the suction strainer screens in place.